Over the last few years, there has been a surge in lawsuits over misleading food labels. In 2010, there were just 45 class-action lawsuits recorded against food and drink companies. But in 2020, that figure hit an anxiety-inducing 220.

So, what’s changed? In a word: activism.

Brands and food products are being called out for greenwashing on their packaging. This includes things like claiming your product is “recyclable” when, in fact, it has to be returned to the supermarket or a specialist waste processing facility to be recycled. (You know, something people would never actually do.)

So, let’s look at what label compliance is and the key things to look out for on your product label. Plus, how label design software can help you set up a robust process to make sure your product labels are always compliant.

The fast way to get feedback on packaging

Get clear and collaborative comments right on top of your packaging artwork.

What is label compliance and who sets the rules?

Label compliance is the process of making sure a product’s label meets all the rules and regulations for the market it’s being sold in. This varies depending on the country and industry.

Here are a few of the key organizations responsible for setting product labeling requirements:

- The Food and Drug Administration (FDA) – responsible for developing regulations in the US based on the Fair Packaging and Labeling Act and other laws

- The European Food Safety Authority (EFSA) – provides independent scientific advice on food-related risks and what to include on product labels

- European Medicines Agency (EMA) – provides practical advice on how to draw up product information for human medicines for pharmaceutical labels and leaflets

- Medicines and Healthcare products Regulatory Agency (MHRA) – approves all packaging and labeling information for medicines sold in the UK

- Food Standards Agency (FSA) – sets the guidelines on all food packaging sold in the UK

Nine things to look out for to keep your packaging and labeling compliant

Whether you’re selling food, cosmetics, medical devices, consumer commodities, or even power tools, you need to put your packaging labels under the microscope to make sure they meet regulations.

The first place you’ll want to look is the principal display panel – that’s the part on the front of the product label that tells consumers everything they need to know at a glance.

You should always check which labeling regulations require your attention based on the industry you’re in. But here’s a roundup of the most common elements required by the FDA, EFSA, and FSA:

- Name of the product

- Ingredient list, including quantities for each ingredient

- Allergy information

- Best before and use by dates

- Country of origin

- Name and address of the business or manufacturer

- Net quantity of the product

- Advice for storage

- Usage instructions

Depending on the local industry standards for your product, you may also need to include things like:

- Alcohol levels

- Nutritional declarations

- Warnings for consumer commodity products

Why compliant labeling is essential to ensure consumer safety

Use within three days of opening. May contain nuts. Avoid contact with eyes.

Behind every must-have message or warning on your product’s package is a story. And while we all like to think we have common sense, some things aren’t worth the risk – both for your customers and for your finances.

Here are a few things correct labeling can help you avoid:

- Food being consumed after developing harmful bacteria

- Allergic reactions to ingredients that could prove fatal

- Tools or hazardous chemicals causing serious injury

So whatever industry you want to sell products in, it’s vital to meet the local packaging and labeling requirements.

How to make sure your label designs are always compliant

The simplest way to create compliant labels is by using packaging design software like Filestage to proof your content before it goes through to artwork and print.

Let’s look at three ways this can help you.

1. Bring content, creators, and stakeholders together in one place

Getting product packages and labels right requires a lot of collaboration.

On any given project, you’ll be working with a range of brand and product people across your organization. And if you’re in a distributed team or are collaborating with an agency, you’ll need somewhere to share designs and get aligned.

Filestage’s design approval software gives you exactly that. You can create a dedicated project with review steps for key stakeholder groups. And if you have multiple files to review, you’ll be able to access them all in one place.

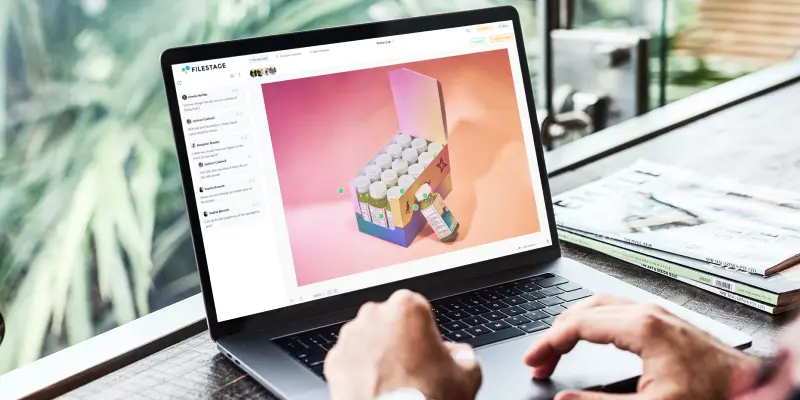

2. Collect visual feedback on your labels and packaging

Have you ever tried to give feedback on a packaging label over email? It isn’t easy. And the feedback isn’t easy to follow either, which often leads to critical mistakes and adds unnecessary time to the whole process.

When you share feedback in Filestage, all you have to do is click on the design to create a marker. Then you can add comments to PDF files and other design formats – with full context for all to see!

And with zoom, rotate, and annotate features, you can hone in on things like:

- Numerical count – important for drugs or food multipacks

- Net contents – weight and volume, for example

- Additional information – marketing claims

3. Make sure the right version goes to print

After putting measures in place to make sure you meet all the right regulations, the last thing you want to do is send the wrong version to print.

With Filestage’s built-in version control, you and your reviewers are always clear which version is the latest. And with smart security settings like blocking downloads until files are approved, you can make your approval process smooth, slick, and stress-free.

Final thoughts

Label compliance is essential for making sure food products, consumer commodities, and other packaged goods are used or consumed safely.

With a dedicated review and approval tool, you can set up a robust and reliable process for proofing label designs before they go to print. Ready to give it a try? Start a free trial →