Whether you’re a small business owner or a crafty side hustler, creating custom packaging labels is an excellent way to showcase your brand identity, share important information with customers, and seal your deliveries in style.

Seven in 10 customers say packaging design can influence their purchasing decision, and packaging labels are a sure-fire way to make your product packaging stand out from the crowd.

In this guide, we’ll walk you through the process of creating your own packaging labels, from designing eye-catching styles through to proofing and printing them.

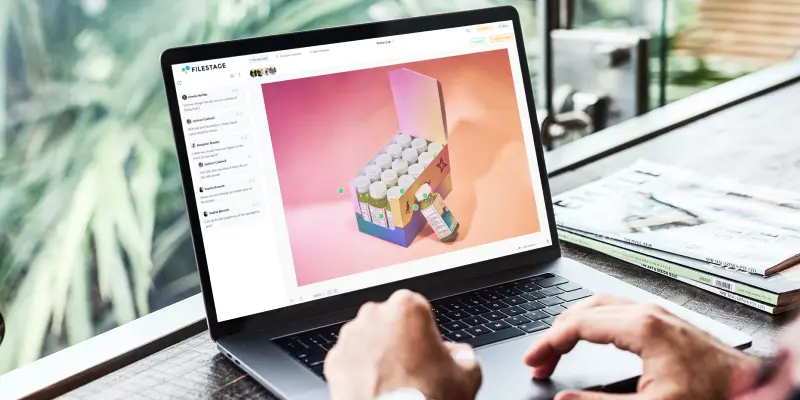

The fast way to get feedback on packaging

Get clear and collaborative comments right on top of your packaging artwork.

The different types of packaging labels

There are a wide range of packaging labels you might want to consider, depending on your products and your priorities. Here are some of the most commonly used labels:

- Brand or product labels – to showcase the name of the product or your brand to boost brand image and awareness

- Ingredient and nutritional tags – to list ingredients and nutritional information, and to inform customers about potential allergens or specific dietary requirements

- Barcodes – to help with product identification, inventory management, and pricing at the point of sale

- Handling/storage markers – to provide instructions for proper handling, storage conditions, and shelf life of the product

- Safety markers – to raise awareness of any safety precautions, hazard warnings, or usage instructions for products that might pose some form of risk

Once you’ve decided on the types of label packaging you need, it’s time to get creative! Need some inspiration? Check out our roundup of the latest packaging design trends.

Source: Dieline

How to design your own packaging labels

Roll up your sleeves, pull up your chair, and get ready to create custom product packaging that’ll catch your customers’ attention and enhance the look of your product packaging.

Research your target audience and competitors

Start by spending some time researching your target audience. You’ve likely already got a pretty good idea of who they are and what they like, but dig deeper to identify current trends and preferences. You could even host a focus group or share an online survey to learn what they’d find most helpful and most visually appealing.

Then turn your attention to your competitors. What do their packaging labels look like? What information do they include? How can you make your custom labels better than theirs? With some solid research, you’ll be on track to create standout labels that will appeal to your audience and get your products front of mind.

Keep it on brand

Consistency is key when it comes to branding. Your packaging labels should align with your overall identity, including your logo, color scheme, fonts, and tone of voice. Think of it like this: your audience should be able to recognize your label and instantly associate it with your brand.

Want to see some examples? Check out our roundup of the best designs for cookie packaging.

Decide on the shape

Labels come in a wide range of shapes and sizes, so choose one that complements your product and its packaging, and aligns with your company’s image. Standard shapes for packaging labels include rectangle, square, round, and oval. But there’s nothing stopping you from going for custom shapes! Unique, cut-to-size labels can add a sense of fun, playfulness, and creativity – if these are qualities that resonate with your brand, then get experimental!

Use an online design tool for a professional-looking label

Online design tools like Adobe Illustrator and Microsoft Publisher make it easier than ever to design professional-looking labels. These tools offer a range of pre-made templates, fonts, images, and graphics, so even non-designers can achieve a thing of beauty! Check out our guide to the best packaging design software and choose a tool that suits your skill level.

When designing your labels, make sure they’re super clear and easy to read, no matter what size labels you’re working with. And make sure your design scales well too. Ultimately, you want everyone to enjoy your labels and read all the important info without straining their eyes!

Check out our full guide to label design for more tips and inspiration!

And once you’re happy with your custom design, it’s time for the all important proofing part of the packaging management process.

Proof your labels to make sure they’re error-free before printing

After all that hard work, imagine how frustrating it would be to go to print, only to find a silly mistake once you’ve already printed a large batch. Beyond frustrating – devastating! That’s why the design review process is an important step.

The best way to proof your packaging labels is with an online proofing tool like Filestage. Filestage is a review and approval platform that’s used by global consumer goods companies including Capri-Sun and Who Gives A Crap. This software makes it easy to share, discuss, and review your packaging label designs with colleagues and external stakeholders.

Here are a few ways Filestage helps with your label design reviews:

- Set up project workflows to manage all your packaging label assets and stakeholders in one place

- Get fast and accurate feedback with point-and-click comments and visual annotations

- Zoom in and rotate your designs to give feedback on every detail

- Keep versions organized in one platform so you can easily see the evolution of your designs

- Compare versions side by side to make sure everyone’s feedback has been met

- Set due dates to keep your project on track and help you meet deadlines

- Track approvals and change requests at a glance from your dashboard

Once the first round of feedback has been implemented, you can easily upload a new version of your packaging label design, and each stakeholder can give their approval. The tool is also helpful for companies in regulated industries, making it easier to create accurate and compliant, food, legal, or pharmaceutical labels.

When you’re confident that your product packaging is error-free and good to go, all that’s left to do is get printing!

“Filestage is our centralized platform for clients to go in and review and approve every design we upload. The whole process is streamlined and we have a tracked record that shows our clients when they review the comments and the date that they approved it.”

Mark Stern, CEO at Custom Box Agency

The fast way to get feedback on packaging

Get clear and collaborative comments right on top of your packaging artwork.

How to print your own packaging labels

When it comes to printing your packaging labels, you have a couple of options: using professional printing services or taking the DIY route. The route you choose to go down will depend on the quantity of labels you’re looking to print, the shape of the labels, and whether you want roll labels or you’re happy with sheets instead.

Let’s take a look at the two options.

Print packaging labels yourself

If you’re working with small quantities or a tight budget, you can print labels yourself, DIY style. To print at home (or from your office), you’ll need a reliable printer and suitable label or sticker paper. Make sure you choose sticker paper that’s compatible with your printer, and always perform test prints first before committing to a large batch.

If you choose to go down this route, you’ll generally want to stick to rectangular or square-shaped labels. That way, it’s fairly easy to align and cut your labels using a paper trimmer or scissors. Other custom shapes are much harder to cut – and precision is key if you want a professional finish.

If you’ve got your heart set on custom, cut-to-size labels, then working with a professional printing service will generally be the better option.

Use professional printing services

If you want an ultra-polished and professional look, consider partnering with a printing company for your print job. They’ll have the expertise, equipment, and resources to deliver high-quality custom labels in large batches – from hundreds to thousands! Vibrant colors? Check. Sharp details? Check. Custom sizes? Check!

You’ll also often be able to pick from a number of materials and finishes to take your labels to the next level. We’ll take a look at those in more detail in just a minute.

Professional printers will usually deliver your labels to you in the form of roll labels. Roll labels are individually cut labels printed on a continuous roll, typically wound around a cardboard or plastic core. They’re particularly beneficial when you’re labeling large quantities of products or packaging, especially when you pair them with label dispensers for ultimate efficiency. Peel, stick, rave, repeat!

Materials and finishes

Choosing the right product packaging materials and finishes can have a huge impact on both their look and durability. Here are some popular material options:

- Paper – paper packaging are versatile and cost-effective. They can come in different finishes like matte or glossy, and they’re best suited to indoor use.

- Waterproof vinyl – vinyl labels are durable and water resistant. They’re ideal for products exposed to moisture or the great outdoors. You can use this material to make stickers for bottles or some other elements of your package.

- Clear – clear labels are also water resistant. They provide a sleek, no-label look, allowing your product packaging to show through.

- Kraft paper – kraft paper packaging provide a natural, rustic feel and are often used for organic or eco-friendly products. They are also recyclable for sustainability points!

- Finishes – custom finishes can elevate the appearance of your packaging. Popular options include a glass, mirror-gloss, or a matte finish.

Final thoughts

Creating your own packaging label is a fantastic way to showcase your brand’s personality, share important information with customers, and catch your customers’ attention. If you’d like to set up your label design process with Filestage to make sure your labels are error-free before you print, start a free trial →