Packaging management is a critical and often underestimated aspect of business operations. From the intricacies of the supply chain to the final stages of distribution, effective packaging management is the piece of the puzzle that ensures products reach customers in optimum condition.

Detail is among the most important things when it comes to packaging. We must choose materials that balance competence, protection, and sustainability, as well as creating eye-catching designs that communicate your brand effectively.

Packaging management requires seamless coordination and communication across departments such as suppliers, designers, manufacturers, QC, and transport.

As products travel from supplier to customer, packing becomes the guardian of the product’s integrity. Packaging not only prevents damage, but enhances efficiency, minimizes waste, and reduces costs.

As environmental responsibility grows, it’s important that we consider sustainability in great detail when thinking about packaging – how can packaging be generated more sustainably? And how can it be made sustainable for consumers?

According to the United States Environmental Protection Agency, 82,220 tonnes of packaging was generated in 2018 in the US alone. Just over 50% of it was recycled, and 38,470 tonnes went to landfill.

In this article, we’ll explore all aspects of the packaging industry. Strategies, design processes, proofing, printing, and distributing packaging – plus tips on how packaging design software can help every step of the way.

We’ll be unraveling a product’s packaging and its key benefits, from the beginning of the supply chain to its final stages before finding its way into the customer’s hands, and how it plays a pivotal role and shaping the customer experience.

The fast way to get feedback on packaging

Get clear and collaborative comments right on top of your packaging artwork.

What is packaging management?

Packaging management is the system which ensures products are looking and working their best. It’s the mastermind that chooses the best materials, sizes, designs, and functions to protect the product inside (and make it look nice).

Aesthetics is important. Packaging needs to look good, but it’s not everything. Packing management is a mix of practicality, functionality, and style. It’s about matching the right packaging to the right product, ensuring it’s protected during its journey from manufacturer to customer.

This process is a team effort, where different departments work together to ensure that every detail is on point and functioning perfectly.

From package design to QC, packaging management is a cyclical process. It’s about creating a memorable unboxing experience for the customer, while keeping it sustainable, cost-effective, and secure.

In a nutshell, graphic design project management or a packaging management is the backbone of a product, creating an enjoyable customer experience while keeping products safe and sound along the way.

Five essential functions of the packaging management process

- Protection: Packaging serves to keep the product safe in transit, while it’s in storage, and going through handling. It keeps the product safe from external factors like moisture, dust, and temperature changes. This is especially important for food products or pharma packaging.

- Branding: Packaging design is integral to a business’s branding. When designing packaging, we should consider the use of colors, graphics, and logos. Product branding separates a product from its competitors, and makes it easily recognizable at a glance. We all know what a pink ‘B’ and a yellow ‘M’ means when we see one.

- Compliance: All packaging must comply with governmental health and safety regulations, ensuring that it’s labeled with safety hazards and instructions on how to open the product. Learn more about label and packaging compliance.

- Sustainability: As previously mentioned, almost half of the packaging generated in the US goes straight to landfill. Brands must ensure that they’re using sustainable materials when creating packaging, abiding by environmental regulations, and urging customers to recycle.

- Cost-effectiveness: Packaging management is a big win-win when it’s cost-effective for manufacturer and consumer. This can be accomplished by picking materials and designs that are effective and budget-friendly. After all, just a few cents difference in unit prices can work out to huge cost savings at scale.

How to manage the packaging design process

Managing the design process is an important aspect of effective packaging management, ensuring that products not only reach their desired destination in perfect condition, but also create a memorable experience for the customer.

The intricate and lengthy process requires a mix of creativity, logistics, and customer-centric thinking while aligning with the broader goals of the supply chain, and the overall packaging management strategy.

Let’s look at the key things you’ll need to manage during your packaging design process.

1. Create a design that brings your brand to life

The first step of packaging design management is to understand the product, the target audience, and the brand’s identity.

It’s about more than just aesthetics. Of course it helps if the product looks good, but it’s really about the customers. When design aligns with the brand’s values and speaks to the customer, it forms a sense of connection between business, product, and consumer.

Need some inspiration? Check out our favorite packaging design trends.

2. Set up processes for fast and centralized collaboration

One thing to remember: design collaboration is key. The design process involves close communication between all divisions, specifically the design teams, marketing teams, and supply chain managers.

These collaborative efforts lead to top-notch packaging design that combines functionality and creativity. This is where materials, packaging size, durability, and attractiveness are all considered to ensure the product remains intact through the supply chain and comes out the other size looking great!

3. Work out your budget and stick to it

Another extremely important consideration is cost-effectiveness. Businesses are always looking to reduce costs. Packaging management is about finding the sweet spot between design quality and budgeting. Efficient materials and streamlined designs can help reduce costs without compromising on protection or aesthetics.

4. Think about sustainability from the start

Reducing environmental impact is increasingly essential in today’s eco-conscious world. Packaging design plays a vital role in sustainability efforts. By utilizing eco-friendly materials, optimizing packaging size to minimize waste, and incorporating recyclability, the design process can contribute significantly to a brand’s environmental responsibility.

By curating eco-friendly materials, optimizing the packaging size to reduce waste, and incorporating recyclability, the design process can contribute hugely to a brand’s environmental responsibility, by way of labeling, infographics, and instructions.

5. Test your packaging with prototypes

The testing stages are crucial in managing packaging design. By creating prototypes, manufacturers and supply chain managers can really get a feel for whether they’re working, helping to identify potential flaws and areas of improvement.

This process ensures that the final design meets functionality, aesthetic criteria, and aligns with the health and safety within the packaging management strategy. Every business needs continuous improvement.

6. Move with the times

The packaging world is ever evolving, so packaging management must be adaptable. Where trends change, customer’s wants and needs shift, and technology advances, effective packaging management requires a constantly evolving roadmap.

For supply chain managers and stakeholders to keep their packaging strategies as malleable as possible, packaging must be regularly assessed via customer feedback, market trends, and supply chain efficiencies.

Proofing: how to get your packaging artwork ready for print

Designers and supply chain managers must proof and approve the packaging artwork before it’s printed. This is a critical step in the process that ensures the final product matches the vision, aligns with the brand, and passes quality control.

As you probably know, sending large design files via email can be a headache. But by using a purpose-built tool for proofing your packaging, you can prevent expensive errors and delays in production – not to mention thousands wasted in reprinting costs.

Here’s how to effectively proof your packaging artwork before sending it to the printers:

- Review – All text, graphics, logos, and other design elements must be carefully examined. It’s important that all copy is checked for spelling and grammar errors, as well as any stark differences in color, font, and sizing. All essential information such as product details, descriptions, barcodes, and legal requirements are included.

- Color reproduction – It must be ensured that the colors in your packaging artwork match what’s intended. To do this, you can use color swatches and Pantone references to keep it consistent. Do remember that colors can appear differently on different screens, so it’s important that you use a color-calibrated monitor, like Eizo.

- Image quality – Aim for a minimum resolution of 300 PPI (pixels per inch) to ensure that your images will print clear as day. If it’s any lower than this, your images can appear pixelated and slightly blurry when printed.

- Dielines and fold – Your packaging may contain unique shapes or folds, it’s important that the dielines and folds are accurately represented in the printed artwork. If it’s incorrectly positioned, it can lead to faulty packaging which is costly and wasteful.

- Proofreading – It cannot be stressed enough how important it is to have fresh eyes look over your work. When proofreading and editing, you can easily become fatigued and overlook errors. So, enlist a team member or two to proofread.

- Print test proofs – It’s always handy to print test proofs of your artwork before finalizing. By doing this, you can test color accuracy, dielines and folds, images, and overall appearance. Your proofs will print as a small-scale version of your finalized work, perfect for comparing to your digital versions.

- Barcode and QR Codes – If your packaging needs QR codes or barcodes, the best thing to do is test them with scanners to make sure they are correctly generated and placed on the packaging.

- Version control – By keeping a version history on file, you can keep a clear vision of your artwork. Use file-naming conventions that indicate each version by date, so you know which version to send for printing.

- Communication – It’s important to maintain communication with your print provider. With them, you can discuss specific printing requirements, flag potential issues, and ensure a smooth and easy printing process.

Want to dive into this topic in more detail? Check out our article on designing and proofing packaging labels.

The fast way to get feedback on packaging

Get clear and collaborative comments right on top of your packaging artwork.

How to print and distribute your packaging

Printing and distributing packaging requires a collaborative and coordinated effort that combines the intricacies of the supply chain, packaging management or a design approval software, and effective supply chain management strategies.

- Choose the right printing partner – Choosing a reputable printing partner is imperative for a smooth printing process. Work closely with them to ensure that they can supply the correct materials and your design specs are translated accurately into the final print.

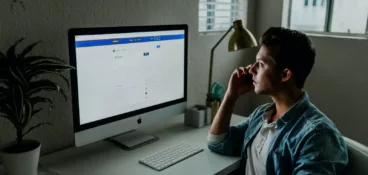

- Use packaging management software – Packaging management software will assist you through the whole packaging process. These tools help you manage your artwork, control version history, and house collaborative tools where you can work with stakeholders seamlessly.

- Pre-press proofing – You can request pre-press proofs (try saying that three times) from your printing partner, giving you a physical representation of the final product for review.

- Batch printing – Of course, this is all dependent on your product’s demand and if you have space to store them. If you have a high demand and enough space, consider printing in batches so you can manage inventory to avoid waste or storage issues.

- Supply chain management – Align your packaging production with your supply chain management strategy. Plan your printing timeline to work alongside your product launch and collaborate with logistic partners to optimize inventory management.

- Quality control – Everything needs quality control. With packaging, it’s important that the product is run through QC before and after printing. This includes checking for consistency in artwork, checking for defects, and that it adhered by health and safety regulations.

- Labeling – Once printed, assembled, labeled, and packaged to be sent off, you must ensure that all necessary labels, barcodes, health and safety information, and recyclability information are present.

- Distribution channels – Establish your distribution channels. Whether it’s through retailers, e-comm platforms, or direct-to-consumer, your packaging should cater to each distribution channel’s requirements.

- Warehousing – If you have a significant demand for products, it’s important that you invest in space. Storage space ensures that your packaging is kept in pristine, temperature-controlled condition.

- Real-time tracking and logistics – We’ve all sat refreshing our emails to check if our parcel has been dispatched, so it’s super important that real-time tracking is available to customers. It also helps distributors, assists in monitoring inventory levels, replenishments, and optimizing management. Logistics is important, too, as communication with logistic partners will ensure that your packaging is transported safely and efficiently.

- Customer satisfaction – It’s all about the customer satisfaction, so, consider the unboxing experience for your customers. Your packaging must be physically engaging for a touch of excitement, while also protecting the product.

Sustainability in packaging management

In an increasingly eco-friendly world, we’re always looking for ways to improve sustainability in packaging. It’s up to the packaging process (and, well, everyone) to ensure that they’re working and living as sustainably as possible.

It’s a responsible choice for businesses, as well as a crucial step towards reducing environmental impact. That being said, here’s a little ‘how to’ on making the packaging process more sustainable:

- Select the right materials – Seek eco-friendly packaging materials and go for the recyclable, recycled, and biodegradable options. These materials minimize the environmental footprint, reducing the amount of waste in landfill.

- Minimalistic designs – Less is more, so embrace minimalist packaging designs that prioritize functionality, and reduce the use of excess materials. By doing this, you’ll conserve energy, resources, and convey a sustainable brand ideal to customers.

- Size your packaging correctly – Use the space by choosing packaging sizes that match the dimensions of your product closely to avoid unnecessary waste and increased transportation, as well as transportation costs.

- Reduce, reuse, recycle – Opt for packaging that can be easily reused or recycled. For example, a sturdy box could be reused by customers within the home. Recycling instructions must be communicated on the packaging so customers can dispose of it properly.

- Biodegradable inks – Some inks make materials unrecyclable, so opt for eco-friendly inks that break down without contributing to pollution. Biodegradable inks are a greener alternative to outdated printing methods.

- Lighten up – Lightweight packaging solutions reduce material consumption, as well as lowering transportation costs and emissions due to reduced weight.

- Understand the lifecycle – Analyze the lifecycle of your packaging to understand its environmental impact, from production to disposal on the customer end. This’ll help you identify areas of improvement and show what you’re doing right.

- Energy-efficient manufacturing – Communicate with your manufacturers to find the most energy-efficient options in your production process to reduce your businesses carbon footprint.

- Communication – Clearly and directly communicate your commitment to sustainability through your product labels and marketing materials so your customers know you’re doing what you can.

By integrating these strategies into your packaging management approach, you can contribute significantly to conserving the environment and appealing to customers to do the same with your product and packaging.

10 cost-saving packaging management tips

Cost-cutting is a constant job to ensure that profit and packaging processes are constantly improving. Here’s some practical cost-saving tips or the packaging process:

- Bulk purchasing – Not only should you be conscious of buying the most cost-efficient materials per unit, but also buying in bulk. Buying in larger quantities often comes at a cheaper cost with heavy discounts.

- Standardization – Standardizing your packing sizes and designs will simplify the production process. This will reduce waste from design changes and decrease material costs.

- Lightweight packaging – Lightweight materials that still offer adequate protection reduce transportation costs, which leads to lower shipping costs.

- Save the planet – Opt for eco-friendly packaging materials that are as efficient as they are sustainable. This way, you can cut costs in the long run due to material efficiency and customer satisfaction.

- Negotiate – Negotiate with your packaging suppliers to seek competitive pricing, discounts on bulk orders, or even stray away and explore new partnerships that can help you save money.

- Streamline production – Optimize usage, minimize downtime, and reduce labor costs by implementing efficient and effective production processes.

- Automation – Automate where possible. By using automated packaging equipment, you can increase speed, reduce errors, and lower labor costs.

- Transportation – Use up space efficiently, whether it’s utilizing all the space in a truck or shipping container. Optimizing the way you package products can reduce shipping costs significantly.

- Keep it energy efficient – Implement energy efficiency in your packaging facility. Use efficient lighting, an HVAC system as opposed to separate heating and air con and optimize your equipment usage to reduce utility bills.

- Improve – Continuously review your packaging process and systems to find potential areas of improvement and cost-cutting solutions.

Final thoughts

In the journey from design to supply chain distribution, the packaging process is an essential force in any product-based business. It safeguards products and elevates customer experiences – not to mention the amount of work that goes into its creation, from design all the way to packaging.

In a world with heightened environmental awareness and a drive to be more sustainable, sustainable packaging practices are not just good for branding, but imperative for its contribution to sustainability.

Eco-friendly materials, minimalist designs, and energy-efficient practices are all things that contribute towards a better planet. So, integrating these strategies will build a brand that embodies meaningful change.

The process from packaging conception to its distribution is a long, intricate journey, from creating relationships with suppliers, to proof printing, all the way to customer feedback. If you need a smarter way to share your designs, review them with stakeholders, and track approvals and translations, start a free trial of Filestage today!